8 New Materials with Game-Changing Properties

8 New Materials with Game-Changing Properties

As advanced manufacturing technologies develop, so does the work of researchers developing new materials. Some may eventually be commercialized and replace materials now being used.

With the advance of new manufacturing technologies, including additive manufacturing, material scientists are developing new materials that have amazing new properties that, once commercialized, will relegate many of today’s cutting-edge materials obsolete. Here are eight impressive new material announcements, including the toughest material ever recorded.

Scientists at the University of Chicago have created a material that behaves like plastic but is also an electrical conductor. It consists of layers of nickel, carbon, and sulfur atoms that maintain a disordered molecular structure. This unique combination of structure and chemistry makes it very resistant to heat, cold, moisture, and harsh chemicals. It is also easy to manufacture at room temperature. Team member and chemistry professor John Anderson likened it to conductive Play-Doh, noting it can be smashed into place and conduct electricity.

NASA scientists recently developed a metal alloy using a 3D-printing process that dramatically improves the strength and durability of the components and parts made from this material, resulting in better and longer-lasting performance. Termed a “nanoscale oxide dispersion strengthened (ODS) alloy,” it can withstand temperatures over 2,000˚ F. The team used a 3D-printing process to distribute nanoscale oxides throughout the alloy, which greatly improved its resistance to high temperatures, making it ideal for aircraft and rocket components.

Scientists have created a new material that has the highest toughness (resistance to permanent deformation) of any material ever recorded. This chromium, cobalt, and nickel (Cr-Co-Ni) alloy is also extremely ductile. Of special note, as the alloy gets colder, its ductility and resistance to fracture actually improve. This is because Cr-Co-Ni is in a class of metals called high-entropy alloys (HEAs): the equal proportions of each constituent element result in higher strength and ductility when stressed.

Become a Member: How to Join ASME

A new super-elastic metal alloy discovered by researchers at Tohoku University in Japan could be the perfect material for joint implants. Common metal materials of nickel and titanium in hip or knee joint replacements are stiffer than bone, which can lead to bone loss; flexible materials in implants, however, lose their wear resistance over time. This super-elastic material could solve both these problems—it bends like bone, exhibits superior wear resistance, and has a strain recovery rate twice that of commercially available nickel-titanium alloys.

Engineers at the University of Wisconsin-Madison have designed a new carbon nanotube-based foam that promises superior protection against concussions. Foam in helmets made from this lightweight, ultra-shock-absorbing foam show 18 times greater energy absorption than the foam currently used in U.S. military combat helmet liners. Tests showed that a vertical orientation of the carbon nanotubes, packed tightly together, provided the most effective shock absorption.

Using an innovative manufacturing process, researchers at the University of California have created an ultra-lightweight metallic microlattice that is 99.99 percent air. The 0.01 percent of solid material (nickel-phosphorus alloy) was engineered at the nanoscale, creating a lattice of interconnected hollow tubes whose walls are only 100 nanometers thick (1,000 times thinner than a human hair). Despite the light weight, the material is strong, flexible, and resists high heat, pressure, and vibrations.

More for You: New Nanomaterial Proves Stronger than Kevlar

Made from two natural ingredients—hemp hurd and mycelium—fungal foam mushroom packaging is a high-performance, water-resistant, insulating, and completely biodegradable material that competes well against petroleum-based and non-biodegradable plastic foams. For example, Evocative Design generates a 3D model (growth tray) using customer-specific dimensions, which is then packed with the ingredients. These are completely grown in seven days, used as shipping materials, and then can be home-composted within 45 days.

Material scientists do like a challenge. Engineers at Northeastern University and the University of Cambridge recently announced they have created a material that does not exist naturally on Earth. The compound, a nickel-iron alloy called tetrataenite, has only been found in meteorites and can withstand tremendous pressures and temperatures. These unique traits are ideal for high-end permanent magnets for advanced machine applications, such as spaceflight. Permanent magnets in use today require rare-earth elements, at added cost and risk. If synthetic tetrataenite proves to work in industrial applications, magnets could be made that are as good or better than current magnets, at lower cost.

Mark Crawford in a technology writer in Corrales, N.M.

1. Nickel-carbon-sulfur alloy

Scientists at the University of Chicago have created a material that behaves like plastic but is also an electrical conductor. It consists of layers of nickel, carbon, and sulfur atoms that maintain a disordered molecular structure. This unique combination of structure and chemistry makes it very resistant to heat, cold, moisture, and harsh chemicals. It is also easy to manufacture at room temperature. Team member and chemistry professor John Anderson likened it to conductive Play-Doh, noting it can be smashed into place and conduct electricity.

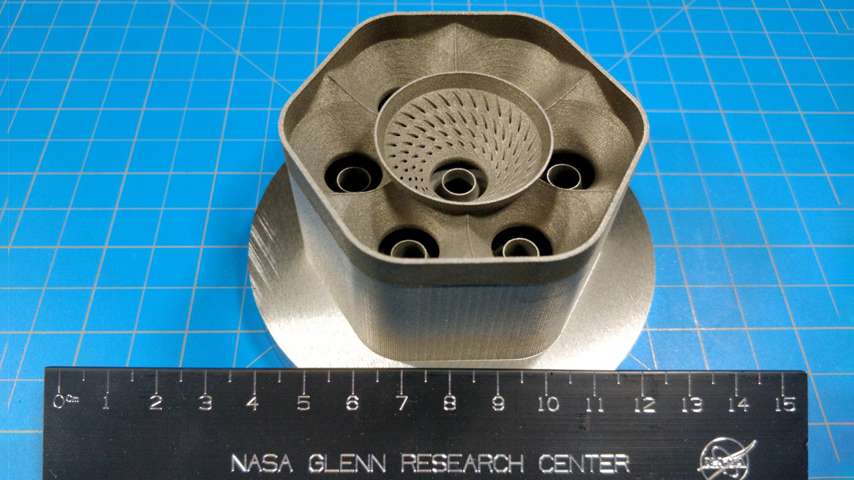

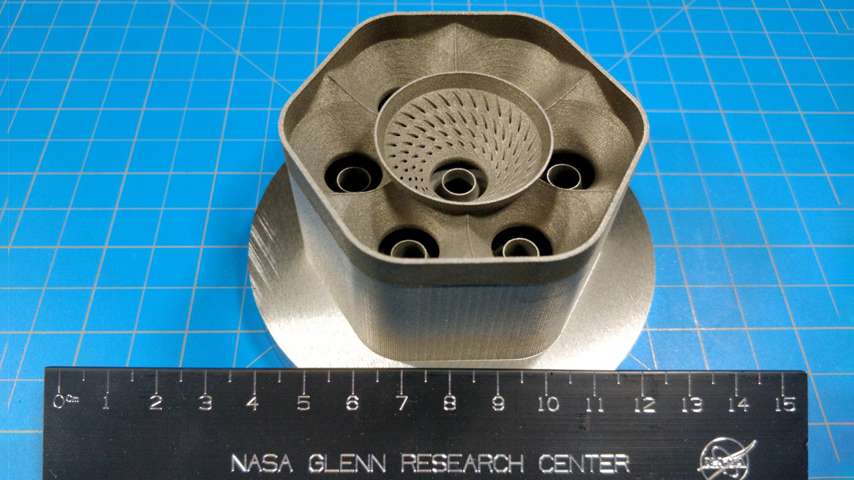

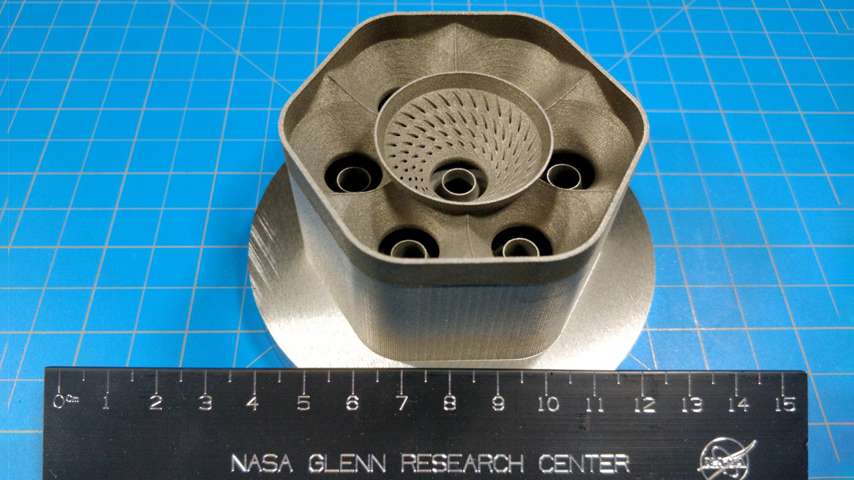

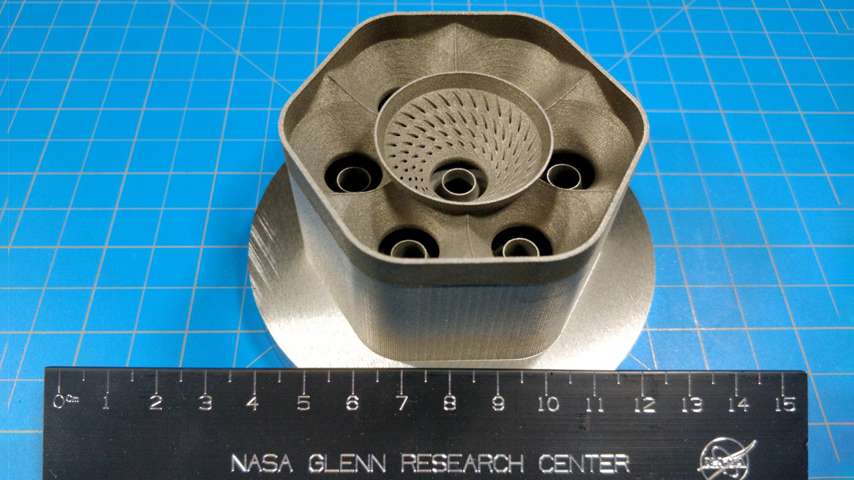

2. NASA alloy GRX-810

NASA scientists recently developed a metal alloy using a 3D-printing process that dramatically improves the strength and durability of the components and parts made from this material, resulting in better and longer-lasting performance. Termed a “nanoscale oxide dispersion strengthened (ODS) alloy,” it can withstand temperatures over 2,000˚ F. The team used a 3D-printing process to distribute nanoscale oxides throughout the alloy, which greatly improved its resistance to high temperatures, making it ideal for aircraft and rocket components.

3. High-entropy alloy

Scientists have created a new material that has the highest toughness (resistance to permanent deformation) of any material ever recorded. This chromium, cobalt, and nickel (Cr-Co-Ni) alloy is also extremely ductile. Of special note, as the alloy gets colder, its ductility and resistance to fracture actually improve. This is because Cr-Co-Ni is in a class of metals called high-entropy alloys (HEAs): the equal proportions of each constituent element result in higher strength and ductility when stressed.

Become a Member: How to Join ASME

4. Cobalt-chromium-aluminum-silica alloy

A new super-elastic metal alloy discovered by researchers at Tohoku University in Japan could be the perfect material for joint implants. Common metal materials of nickel and titanium in hip or knee joint replacements are stiffer than bone, which can lead to bone loss; flexible materials in implants, however, lose their wear resistance over time. This super-elastic material could solve both these problems—it bends like bone, exhibits superior wear resistance, and has a strain recovery rate twice that of commercially available nickel-titanium alloys.

5. Carbon nanotube foam

Engineers at the University of Wisconsin-Madison have designed a new carbon nanotube-based foam that promises superior protection against concussions. Foam in helmets made from this lightweight, ultra-shock-absorbing foam show 18 times greater energy absorption than the foam currently used in U.S. military combat helmet liners. Tests showed that a vertical orientation of the carbon nanotubes, packed tightly together, provided the most effective shock absorption.

6. Nickel-phosphorus microlattice

Using an innovative manufacturing process, researchers at the University of California have created an ultra-lightweight metallic microlattice that is 99.99 percent air. The 0.01 percent of solid material (nickel-phosphorus alloy) was engineered at the nanoscale, creating a lattice of interconnected hollow tubes whose walls are only 100 nanometers thick (1,000 times thinner than a human hair). Despite the light weight, the material is strong, flexible, and resists high heat, pressure, and vibrations.

More for You: New Nanomaterial Proves Stronger than Kevlar

7. Fungal foam

Made from two natural ingredients—hemp hurd and mycelium—fungal foam mushroom packaging is a high-performance, water-resistant, insulating, and completely biodegradable material that competes well against petroleum-based and non-biodegradable plastic foams. For example, Evocative Design generates a 3D model (growth tray) using customer-specific dimensions, which is then packed with the ingredients. These are completely grown in seven days, used as shipping materials, and then can be home-composted within 45 days.

8. Out of this world

Material scientists do like a challenge. Engineers at Northeastern University and the University of Cambridge recently announced they have created a material that does not exist naturally on Earth. The compound, a nickel-iron alloy called tetrataenite, has only been found in meteorites and can withstand tremendous pressures and temperatures. These unique traits are ideal for high-end permanent magnets for advanced machine applications, such as spaceflight. Permanent magnets in use today require rare-earth elements, at added cost and risk. If synthetic tetrataenite proves to work in industrial applications, magnets could be made that are as good or better than current magnets, at lower cost.

Mark Crawford in a technology writer in Corrales, N.M.