Low-Temperature Production Could Lead to More Uses for Ammonia

Low-Temperature Production Could Lead to More Uses for Ammonia

Researchers at a national laboratory have developed a method that doesn’t require high temperatures or pressures, which could make the chemical even more widely available.

Ammonia is one of the most widely produced chemicals, with around 150 million metric tons produced each year worldwide. Most of the ammonia produced ends up as fertilizer, although it is also used for cleaning, manufacturing, or as refrigerant for cooling plants.

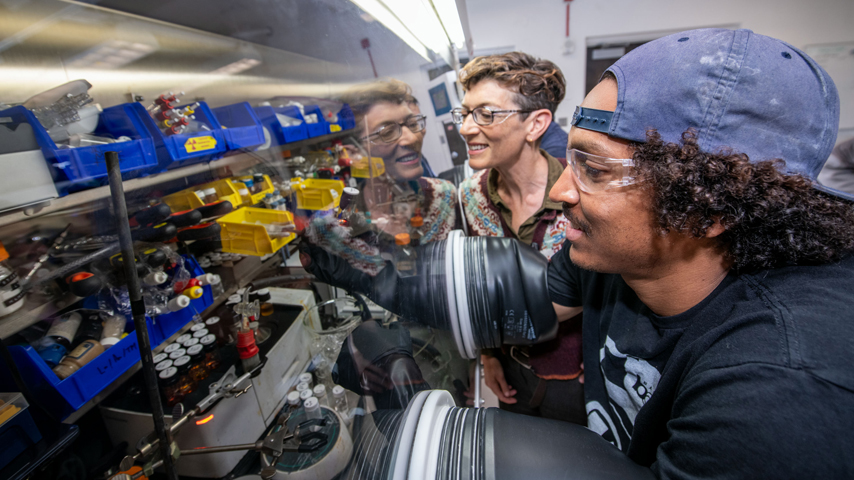

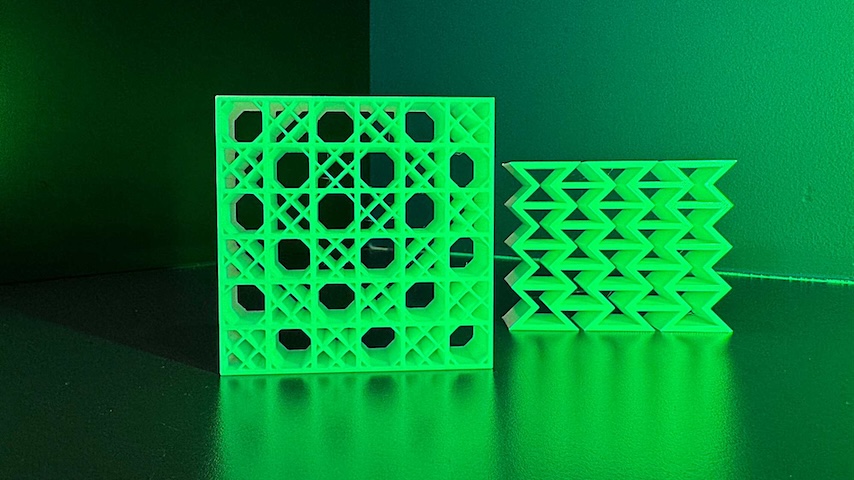

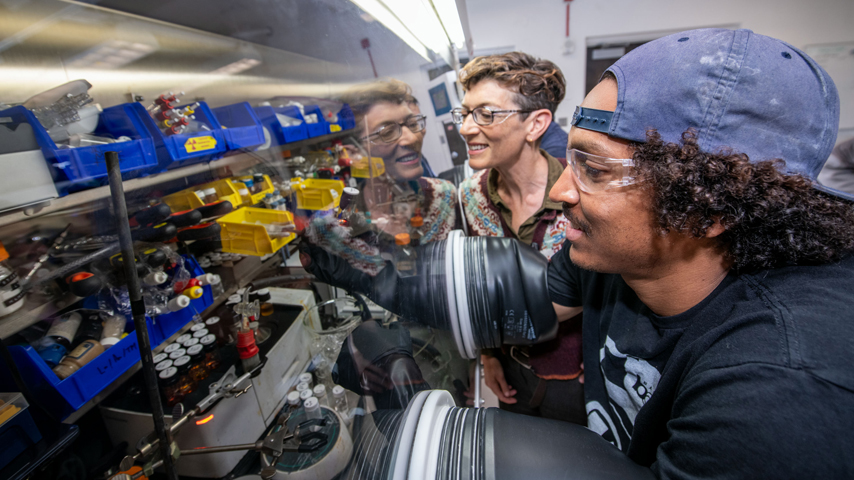

Almost all that ammonia is produced through a process that requires high temperatures and pressure, which means it is energy intensive. Now, researchers at the Lawrence Berkeley National Laboratory (LBNL), a Department of Energy lab in California, have developed an alternative method that requires less energy input.

“We've tried to take inspiration from nature to find a mild way to absorb the nitrogen from the atmosphere and convert it into useful molecules,” explained Polly Arnold, Chemical Sciences Division Director and Professor of Chemistry at LBNL. Arnold led the research team, which included Jaden Lara, Anthony Wong, Matt Hernandez, and Jimmy Liu.

Nitrogen, a critical component of chlorophyll, enables plants to convert light energy into glucose and oxygen. As plants absorbed the nitrogen in the soil, the ammonia in the fertilizer replenished the nitrogen. Despite heavily relying on nitrogen, plants depended on soil sources since they couldn’t absorb it from the atmosphere, which contained approximately 78 percent nitrogen.

Nitrogen, a critical component of chlorophyll, enables plants to convert light energy into glucose and oxygen. As plants absorbed the nitrogen in the soil, the ammonia in the fertilizer replenished the nitrogen. Despite heavily relying on nitrogen, plants depended on soil sources since they couldn’t absorb it from the atmosphere, which contained approximately 78 percent nitrogen.

In the early 1900s, German chemists pioneered the Haber-Bosch process, revolutionizing global ammonia production. Under high temperature and pressure, they passed atmospheric nitrogen (N2) and hydrogen (H2) over metal catalysts to form ammonia (NH3). Refinements over the last century optimized and streamlined the process for large-scale ammonia production.

Despite its energy intensity and high cost, researchers did not aim to replace the Haber-Bosch process for global ammonia production. Instead, they developed a new production method, inspired by nature, to provide ammonia, in a specially protected formula.

The creation of specialized ammonia offers a range of applications, including use as fuel and in food production.

“Instead of making fertilizer, we might go straight to the food product. Rather than having to grow the crops from the ammonia, this would be a way to get to asymmetrically functionalized nitrogen molecules,” Arnold said. Producers could use specialized nitrogen compounds to create food products or supplements, providing essential nutrients without relying on traditional agricultural methods.

More on This Topic: Smoother Sailing with Ammonia

“On a remote site where people don't have access to Haber-Bosch or they can't grow enough crops because their water challenged, we could deliver them a box that contained this catalyst and they could let the nitrogen get absorbed from the air and get the amino acid out of it without ever having to generate hydrogen or ammonia,” Arnold said.

Breaking the strong bond between nitrogen atoms requires electron sources. Initially overlooked, rare earth metals lack the ability to store electrons for this task. However, nitrogen adhered to them in Arnold’s molecules, allowing researchers to immobilize the nitrogen and use a reagent—compounds added to initiate chemical reactions—for separation. Potassium remained a favored reagent and electron source, but researchers aimed to harness electrons directly from sustainable energy sources.

Watch the Video: Cracking Liquid Ammonia

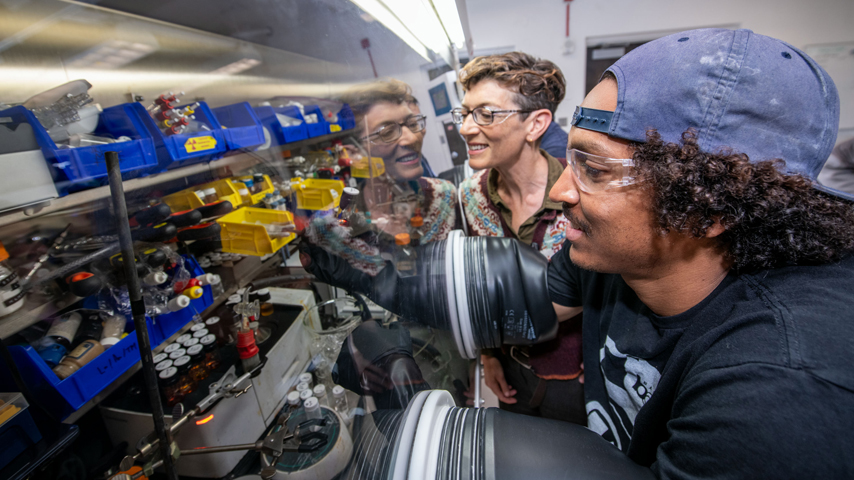

“We made a letterbox shaped construct to help the nitrogen stick to the rare-earth-metal center. We can then pump in electrons from somewhere else and the nitrogen is held by the rare earth metal as it is transformed into the ammonia product,” Arnold said. “The nitrogen bond starts to break, and we start to make new nitrogen-element bonds. The whole structure is flexible and guiding for the electrons and the other reagents, making a catalytic cycle.”

Researchers explored lesser-known rare earth metals to deepen their understanding of how and why these metals interacted with nitrogen in the process. Each lanthanide exhibited unique properties and characteristics, enabling researchers to refine the reaction. Since the lanthanides positioned the nitrogen inside a reactive space, it allowed researchers to break the strong N≡N triple bond and make new N-element bonds. This makes the system more flexible than the traditional Haber Bosch process which makes exclusively nitrogen-hydrogen bonds.

“Fossil fuels are currently carrying hydrogen or energy and chemical bonds around. Ammonia is another way to bring in the electrons from hydrogen and it's compatible with the current systems we have for transporting fossil fuels. It's also safer than hydrogen,” Arnold said. While hydrogen on its own served as a viable fuel source, storage and transportation require high pressure and low temperatures to match the range of today's internal combustion engines.

The Big Picture: Material Limits Impact Infrastructure Plans

Hydrogen derived from ammonia can be used for combustion in fuel cells and is stored more easily than hydrogen alone, as it can be liquified under milder conditions. Combusting ammonia in fuel cells produces nitrogen and water, avoiding typical fossil fuel carbon dioxide emissions. However, incomplete ammonia combustion can generate nitrogen oxides, which are managed with catalytic converters.

Researchers explored using rare earth metals for catalyzing ammonia formation and hope to apply it across diverse fields, from energy production to food manufacturing. These innovations promise to unlock new opportunities for sustainable global development, addressing challenges such as food security, energy transition, and environmental sustainability.

Nicole Imeson is a technology writer in Calgary, Alta.

Almost all that ammonia is produced through a process that requires high temperatures and pressure, which means it is energy intensive. Now, researchers at the Lawrence Berkeley National Laboratory (LBNL), a Department of Energy lab in California, have developed an alternative method that requires less energy input.

“We've tried to take inspiration from nature to find a mild way to absorb the nitrogen from the atmosphere and convert it into useful molecules,” explained Polly Arnold, Chemical Sciences Division Director and Professor of Chemistry at LBNL. Arnold led the research team, which included Jaden Lara, Anthony Wong, Matt Hernandez, and Jimmy Liu.

Engineering Research for You

R&D Pulse examines the frontiers of engineering, an exclusive benefit for ASME members.

In the early 1900s, German chemists pioneered the Haber-Bosch process, revolutionizing global ammonia production. Under high temperature and pressure, they passed atmospheric nitrogen (N2) and hydrogen (H2) over metal catalysts to form ammonia (NH3). Refinements over the last century optimized and streamlined the process for large-scale ammonia production.

Despite its energy intensity and high cost, researchers did not aim to replace the Haber-Bosch process for global ammonia production. Instead, they developed a new production method, inspired by nature, to provide ammonia, in a specially protected formula.

The creation of specialized ammonia offers a range of applications, including use as fuel and in food production.

“Instead of making fertilizer, we might go straight to the food product. Rather than having to grow the crops from the ammonia, this would be a way to get to asymmetrically functionalized nitrogen molecules,” Arnold said. Producers could use specialized nitrogen compounds to create food products or supplements, providing essential nutrients without relying on traditional agricultural methods.

More on This Topic: Smoother Sailing with Ammonia

“On a remote site where people don't have access to Haber-Bosch or they can't grow enough crops because their water challenged, we could deliver them a box that contained this catalyst and they could let the nitrogen get absorbed from the air and get the amino acid out of it without ever having to generate hydrogen or ammonia,” Arnold said.

Rare earth metals

Lanthanides, rare earth metals at the bottom of the periodic table, share chemical properties with other metals but display distinct electronic and magnetic characteristics. Despite their name, rare earth metals aren’t particularly rare but rather have dispersed concentrations that make them challenging and expensive to extract in large quantities.Breaking the strong bond between nitrogen atoms requires electron sources. Initially overlooked, rare earth metals lack the ability to store electrons for this task. However, nitrogen adhered to them in Arnold’s molecules, allowing researchers to immobilize the nitrogen and use a reagent—compounds added to initiate chemical reactions—for separation. Potassium remained a favored reagent and electron source, but researchers aimed to harness electrons directly from sustainable energy sources.

Watch the Video: Cracking Liquid Ammonia

“We made a letterbox shaped construct to help the nitrogen stick to the rare-earth-metal center. We can then pump in electrons from somewhere else and the nitrogen is held by the rare earth metal as it is transformed into the ammonia product,” Arnold said. “The nitrogen bond starts to break, and we start to make new nitrogen-element bonds. The whole structure is flexible and guiding for the electrons and the other reagents, making a catalytic cycle.”

Researchers explored lesser-known rare earth metals to deepen their understanding of how and why these metals interacted with nitrogen in the process. Each lanthanide exhibited unique properties and characteristics, enabling researchers to refine the reaction. Since the lanthanides positioned the nitrogen inside a reactive space, it allowed researchers to break the strong N≡N triple bond and make new N-element bonds. This makes the system more flexible than the traditional Haber Bosch process which makes exclusively nitrogen-hydrogen bonds.

Fuel source applications

In addition to its invaluable use as a fertilizer, industries see ammonia as a promising fuel source for its potential in energy generation and transportation.“Fossil fuels are currently carrying hydrogen or energy and chemical bonds around. Ammonia is another way to bring in the electrons from hydrogen and it's compatible with the current systems we have for transporting fossil fuels. It's also safer than hydrogen,” Arnold said. While hydrogen on its own served as a viable fuel source, storage and transportation require high pressure and low temperatures to match the range of today's internal combustion engines.

The Big Picture: Material Limits Impact Infrastructure Plans

Hydrogen derived from ammonia can be used for combustion in fuel cells and is stored more easily than hydrogen alone, as it can be liquified under milder conditions. Combusting ammonia in fuel cells produces nitrogen and water, avoiding typical fossil fuel carbon dioxide emissions. However, incomplete ammonia combustion can generate nitrogen oxides, which are managed with catalytic converters.

Researchers explored using rare earth metals for catalyzing ammonia formation and hope to apply it across diverse fields, from energy production to food manufacturing. These innovations promise to unlock new opportunities for sustainable global development, addressing challenges such as food security, energy transition, and environmental sustainability.

Nicole Imeson is a technology writer in Calgary, Alta.