Super Soaker Inventor Lonnie Johnson Takes on Green Energy With JTEC

Super Soaker Inventor Lonnie Johnson Takes on Green Energy With JTEC

Mechanical and nuclear engineer Lonnie Johnson is looking to electrify the planet with his latest invention.

Low-temperature heat is available in abundance from both human-made and natural sources. A famed inventor has been developing a device that he says can efficiently scavange these common heat sources to produce electricity, and he believes it soon will be ready for use in factories, utility companies, automobiles, and other entities that lose a significant quantity of potential energy in waste heat.

The Johnson Thermal Electrochemical Converter (JTEC) is a solid-state device uses an efficient process involving hydrogen as a working fluid to transform heat into electricity.

“My motivation for developing the tech was to get away from fossil fuels and things that were destroying the environment,” said JTEC Energy founder and chairman Lonnie Johnson. “Initially, the objective was for solar energy, but as I've learned more, my primary objective right now is actually low, low temperature geothermal.”

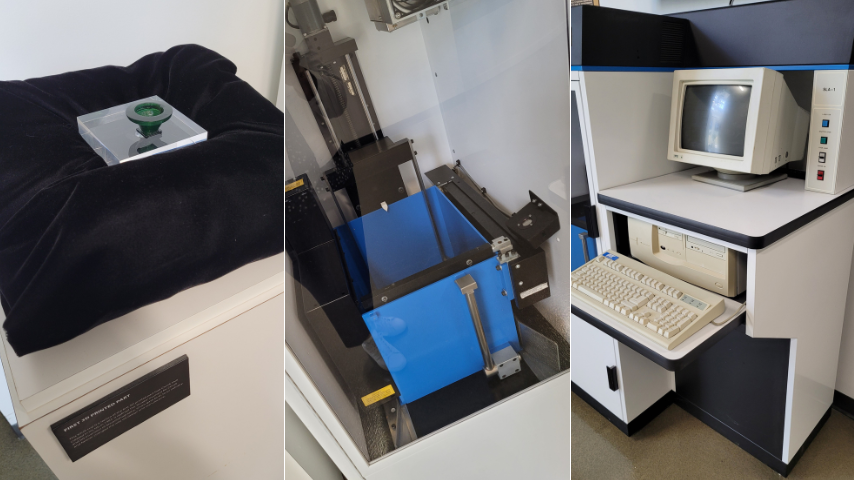

Johnson, a mechanical and nuclear engineer, “accidentally” invented the Super Soaker back in the 1980s while working on an environmentally friendly heat pump that used water instead of Freon. After a leak caused a jet of water to blast out of the heat pump, Johnson saw the potential for a fun squirt gun invention. He built the prototype and patented the concept that would eventually become the 1992 top-selling toy of the year.

Johnson shared that when the Super Soaker became successful as an independent project, he was able to start his own company and fund his laboratory in downtown Atlanta with the revenue.

“I decided to get back to my interest in energy and environment,” he said. “Someone asked if I'd be interested in investing in batteries. As I tell people, Super Soaker spoiled me—if I was going to get involved, I wanted to take it to a whole new performance level. So, I started looking around for what would be the next thing beyond lithium ion.”

Along the way, Johnson got into electrochemistry, developing a curiosity around charging and discharging batteries, materials, electrolytes, and ions—how they flow, the heating, and the thermodynamics.

“I became familiar with the Nernst equation,” shared Johnson. “And with that I said, ‘Geez, I could use this electrochemistry and marry that with thermodynamics and come up with a new type of engine.’”

The JTEC can generate electricity almost anywhere a heat or pressure differential is present, Johnson said. It has no moving parts, making it easier and less expensive to maintain than traditional Stirling engines. The converter requires no input or fuel and does not create exhaust. And like any heat engine, the JTEC becomes a cooling device when run in reverse.

The device runs on the Ericsson thermodynamic cycle and converts heat to electricity at efficiency levels that approach the Carnot limit—the theoretical maximum efficiency of a heat engine. “Our performance goal is about 70 percent of Carnot, and we've gotten test data that indicates it is an achievable goal, so we're excited about that,” Johnson said.

“I like to think of it as an engine because I'm a mechanical engineer,” he continued. “But instead of using pistons and turbines to compress and expand the working fluid gas, we use electrochemistry.”

Johnson explained that all engines work by compressing a gas at low temperature, then heating it up and expanding it at high temperature. It takes less work to do the low temperature compression, he said, and you get a lot more work out of the high temperature expansion—enough, in fact, to drive the low temperature compression process and then still have net work left over.

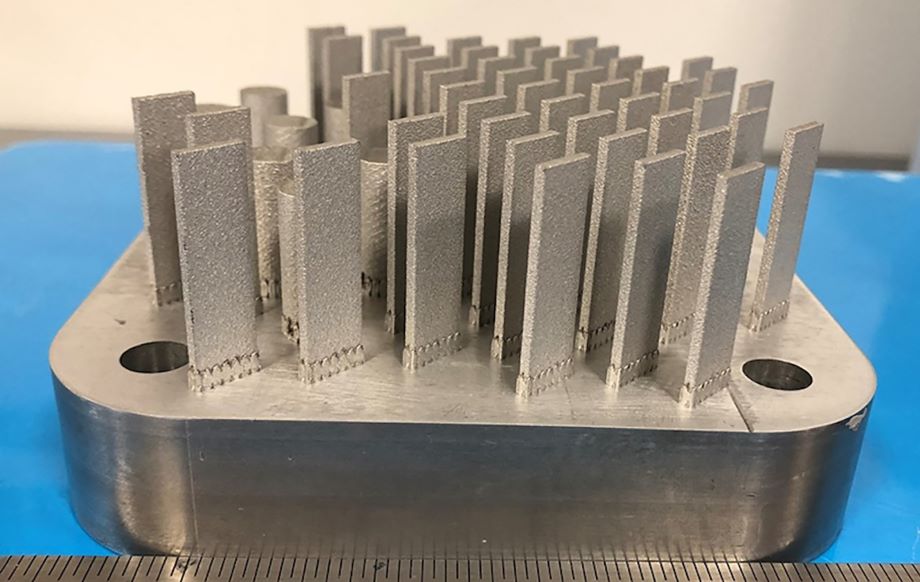

The JTEC engine works similarly, consisting of two stages—a low temperature compression stage and a high temperature power stage—compressing and expanding hydrogen gas. Each stage consists of a working fluid chamber bisected by a membrane electrode assembly (MEA). Instead of mechanical work coming out of the JTEC, what comes out is electricity directly.

“We use the electrochemistry of a proton conductive membrane—not too different from what's in a fuel cell—to compress hydrogen, apply voltage, and drive hydrogen from one side to the other, from low pressure to high pressure,” Johnson said.

“And then we use another membrane that's sitting at a hot temperature to allow it to expand back through the membrane,” he continued. “You get more voltage out of the high temperature expansion and more power—enough to drive the low temperature process.”

The key difference between the JTEC and a fuel cell is that there is no oxygen—only hydrogen gas at different pressure levels that circulate continuously in a closed system as the working fluid. In fuel cells, hydrogen and oxygen react to generate power.

Compared to traditional liquid-based electrochemical converters, Johnson’s device operates in greater temperature ranges. And while other converters—such as alkali-metal thermal to electric converters—employ similar electrochemical reactions to move and pressurize hydrogen, they use corrosive liquid sodium or potassium metal.

According to Johnson, the biggest obstacle JTEC Energy has faced involved materials. Having membrane materials that could handle the pressure differential and would be able to work with hydrogen as a dry gas as opposed to a humidified gas presented a significant challenge.

He explained that proton conducting membranes, particularly those that operate at low temperature, require hydration. If they dry out, their connectivity goes very low, and the peaks go up—and the result is that you can't get any power.

“Over the years we've looked at a lot of different materials and tried a lot of different things. We now have a system that's working,” he shared.

Become a Member: How to Join ASME

“You can come up with a great invention and have all the magic in the world, but if it's not at the right price, it's not going to be commercializable,” Johnson stated. “We are making improvements that will bring the manufacturing cost down because my interest is, of course, commercializing the technology and benefiting from the investment that I made over the years.”

While the first JTEC unit was only a few milliwatts, it’s currently developed to 100 watts. As the device approaches commercialization, he expects it to reach the kilowatt level and then 100 kW level.

“We'll continue to evolve the technology and bring the manufacturing cost down as we iterate this system through the various stages of development,” Johnson said.

Sarah Alburakeh is a strategic content editor.

The Johnson Thermal Electrochemical Converter (JTEC) is a solid-state device uses an efficient process involving hydrogen as a working fluid to transform heat into electricity.

“My motivation for developing the tech was to get away from fossil fuels and things that were destroying the environment,” said JTEC Energy founder and chairman Lonnie Johnson. “Initially, the objective was for solar energy, but as I've learned more, my primary objective right now is actually low, low temperature geothermal.”

From Super Soaker to super power

Johnson, a mechanical and nuclear engineer, “accidentally” invented the Super Soaker back in the 1980s while working on an environmentally friendly heat pump that used water instead of Freon. After a leak caused a jet of water to blast out of the heat pump, Johnson saw the potential for a fun squirt gun invention. He built the prototype and patented the concept that would eventually become the 1992 top-selling toy of the year.

Johnson shared that when the Super Soaker became successful as an independent project, he was able to start his own company and fund his laboratory in downtown Atlanta with the revenue.

“I decided to get back to my interest in energy and environment,” he said. “Someone asked if I'd be interested in investing in batteries. As I tell people, Super Soaker spoiled me—if I was going to get involved, I wanted to take it to a whole new performance level. So, I started looking around for what would be the next thing beyond lithium ion.”

Along the way, Johnson got into electrochemistry, developing a curiosity around charging and discharging batteries, materials, electrolytes, and ions—how they flow, the heating, and the thermodynamics.

“I became familiar with the Nernst equation,” shared Johnson. “And with that I said, ‘Geez, I could use this electrochemistry and marry that with thermodynamics and come up with a new type of engine.’”

Harvesting thermal energy

The JTEC can generate electricity almost anywhere a heat or pressure differential is present, Johnson said. It has no moving parts, making it easier and less expensive to maintain than traditional Stirling engines. The converter requires no input or fuel and does not create exhaust. And like any heat engine, the JTEC becomes a cooling device when run in reverse.

The device runs on the Ericsson thermodynamic cycle and converts heat to electricity at efficiency levels that approach the Carnot limit—the theoretical maximum efficiency of a heat engine. “Our performance goal is about 70 percent of Carnot, and we've gotten test data that indicates it is an achievable goal, so we're excited about that,” Johnson said.

“I like to think of it as an engine because I'm a mechanical engineer,” he continued. “But instead of using pistons and turbines to compress and expand the working fluid gas, we use electrochemistry.”

Johnson explained that all engines work by compressing a gas at low temperature, then heating it up and expanding it at high temperature. It takes less work to do the low temperature compression, he said, and you get a lot more work out of the high temperature expansion—enough, in fact, to drive the low temperature compression process and then still have net work left over.

The JTEC engine works similarly, consisting of two stages—a low temperature compression stage and a high temperature power stage—compressing and expanding hydrogen gas. Each stage consists of a working fluid chamber bisected by a membrane electrode assembly (MEA). Instead of mechanical work coming out of the JTEC, what comes out is electricity directly.

“We use the electrochemistry of a proton conductive membrane—not too different from what's in a fuel cell—to compress hydrogen, apply voltage, and drive hydrogen from one side to the other, from low pressure to high pressure,” Johnson said.

“And then we use another membrane that's sitting at a hot temperature to allow it to expand back through the membrane,” he continued. “You get more voltage out of the high temperature expansion and more power—enough to drive the low temperature process.”

The key difference between the JTEC and a fuel cell is that there is no oxygen—only hydrogen gas at different pressure levels that circulate continuously in a closed system as the working fluid. In fuel cells, hydrogen and oxygen react to generate power.

Compared to traditional liquid-based electrochemical converters, Johnson’s device operates in greater temperature ranges. And while other converters—such as alkali-metal thermal to electric converters—employ similar electrochemical reactions to move and pressurize hydrogen, they use corrosive liquid sodium or potassium metal.

Technological hurdles

According to Johnson, the biggest obstacle JTEC Energy has faced involved materials. Having membrane materials that could handle the pressure differential and would be able to work with hydrogen as a dry gas as opposed to a humidified gas presented a significant challenge.

He explained that proton conducting membranes, particularly those that operate at low temperature, require hydration. If they dry out, their connectivity goes very low, and the peaks go up—and the result is that you can't get any power.

“Over the years we've looked at a lot of different materials and tried a lot of different things. We now have a system that's working,” he shared.

Become a Member: How to Join ASME

“You can come up with a great invention and have all the magic in the world, but if it's not at the right price, it's not going to be commercializable,” Johnson stated. “We are making improvements that will bring the manufacturing cost down because my interest is, of course, commercializing the technology and benefiting from the investment that I made over the years.”

While the first JTEC unit was only a few milliwatts, it’s currently developed to 100 watts. As the device approaches commercialization, he expects it to reach the kilowatt level and then 100 kW level.

“We'll continue to evolve the technology and bring the manufacturing cost down as we iterate this system through the various stages of development,” Johnson said.

Sarah Alburakeh is a strategic content editor.

.gif?width=542&height=338&ext=.gif)