Mobile Robot Prints Customized Designs Where Needed

Mobile Robot Prints Customized Designs Where Needed

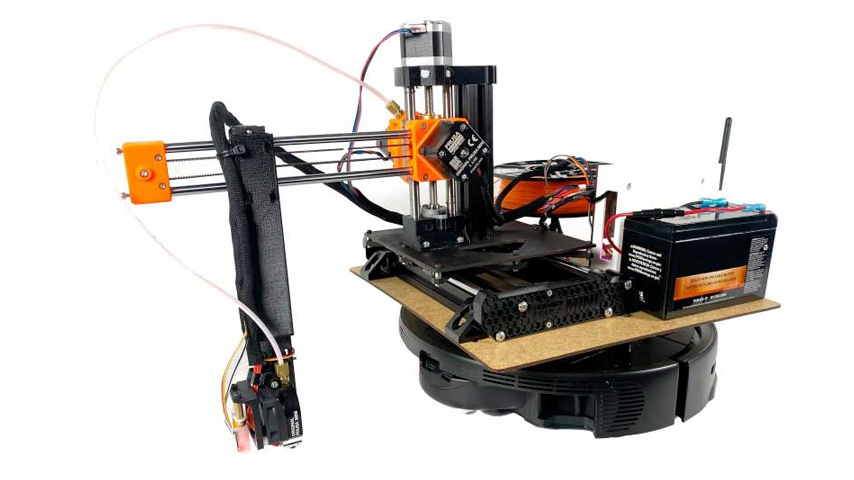

MobiPrint—a mobile 3D printer—can produce custom designs directly where needed to help users with accessibility or to add an extra bit of fun to any living space.

While 3D printing technologies have made it easier for users to quickly design and fabricate objects, they have, historically, lacked the ability to tailor spaces because of their fixed natures.

Now, researchers in Jon Froehlich’s Makeability Lab at the University of Washington (UW), have created a unique mobile 3D printer, MobiPrint, with the power to map out a room and print objects directly on to the floor’s surface.

Liang He, a former graduate student at UW who is now an assistant professor at Purdue University, said he and fellow graduate student Daniel Campos Zamora were first inspired to think about a mobile fabrication device when another colleague mentioned the difficulty navigating a conference space.

“It would be great if we could create something dynamic that could provide some kind of tactile paving for blind users,” He said. “My background was in fabrication, and I thought we could create something that was both dynamic and changeable that could provide those tactile surface indicators.”

Zamora said, initially, he explored different fabrication approaches including vacuum forming and computer numerical control (CNC) milling, but the team kept coming back to 3D printing because of its flexibility.

“This gave us the potential to make new shapes and designs and a certain level of freedom,” he said. “But we then had to take a step back and determine how to make such a fabrication system that also could travel around a space. It’s a completely different approach.”

The team created a prototype leveraging a modified consumer vacuum robot to gain that necessary mobility. He said, once they determined which robot would be best, then they had to figure out a host of other engineering challenges. “How do you tweak a 3D printer so it prints on the floor?” He said. “We had to tweak the board, make it run on a battery and wireless system, and tweak the mechanical structure. We also had to think about how it changes things like slicing and editing.”

Discover the Benefits of ASME Membership

The resulting prototype can autonomously prowl around a designated room, using LIDAR to map out the space. That map is then transformed into an interactive canvas in a design tool where users can select the object they want to build, whether it’s a tactile wayfinding tile or a small cat bowl, as well as the location in which they want to build it. MobiPrint then heads to that precise location, fabricating the item requested on the spot using polylactic acid (PLA), a common bioplastic.

With the success of this initial prototype, Zamora is now considering how to bring MobiPrint to the outdoors.

“Our lab is very passionate about accessibility and addressing social issues,” He said. “We are now thinking about what kind of engineering lift might be required to bring this outside so we could potentially print a curb at an intersection that doesn’t have one to help people who use wheelchairs or tactile wayfinding for those with visual impairment.”

He added that there is power in being able to reconfigure environments. While there are many papers in the scientific literature that talk about using extended reality (XR) applications to direct add objects in situ, a future MobiPrint could potentially allow users to communicate with the printer using VR to modify models on the fly. This would offer users more control and customization to print different objects.

He also said there is value in pursuing a device that can 3D print on the walls or ceiling. “Right now, this kind of printing is focused on the ground,” he said. “But now we are trying to figure out if we could use a drone to print something on the façade or interior walls of a building. You can imagine we could create decorations or scaffoldings for plants. So, we are also exploring how to print on a vertical surface.”

More For You: Miniature Robots to Navigate Blood Vessel Networks

The end goal, He said, is to create a full pipeline of devices that allow users to “design, control, and fabricate.” Zamora agreed—and said he hopes that engineers will start to focus on new ways of integrating or working with 3D printers to change the future of digital fabrication workflows and what they can do to customize spaces.

“It may seem like a simple idea at first—putting a 3D printer on a robotic vacuum,” Zamora said. “But it opens up a lot of bigger questions to explore.” Questions include, “How do you integrate these different systems to add new capabilities?” or “How do you design for a new pipeline of these kinds of machines?”

Zamora added, it may not “make sense to use a typical slicer where you don’t have any information about the environment if your machine now has the ability to get that. There’s a lot we can do to make the environment more accessible or just make it more suited to your needs. We just need to explore these kinds of questions.”

Kayt Sukel is a technology writer and author in Houston, Tex.

Now, researchers in Jon Froehlich’s Makeability Lab at the University of Washington (UW), have created a unique mobile 3D printer, MobiPrint, with the power to map out a room and print objects directly on to the floor’s surface.

Mobile fabrication

Liang He, a former graduate student at UW who is now an assistant professor at Purdue University, said he and fellow graduate student Daniel Campos Zamora were first inspired to think about a mobile fabrication device when another colleague mentioned the difficulty navigating a conference space.“It would be great if we could create something dynamic that could provide some kind of tactile paving for blind users,” He said. “My background was in fabrication, and I thought we could create something that was both dynamic and changeable that could provide those tactile surface indicators.”

Zamora said, initially, he explored different fabrication approaches including vacuum forming and computer numerical control (CNC) milling, but the team kept coming back to 3D printing because of its flexibility.

“This gave us the potential to make new shapes and designs and a certain level of freedom,” he said. “But we then had to take a step back and determine how to make such a fabrication system that also could travel around a space. It’s a completely different approach.”

The team created a prototype leveraging a modified consumer vacuum robot to gain that necessary mobility. He said, once they determined which robot would be best, then they had to figure out a host of other engineering challenges. “How do you tweak a 3D printer so it prints on the floor?” He said. “We had to tweak the board, make it run on a battery and wireless system, and tweak the mechanical structure. We also had to think about how it changes things like slicing and editing.”

Discover the Benefits of ASME Membership

The resulting prototype can autonomously prowl around a designated room, using LIDAR to map out the space. That map is then transformed into an interactive canvas in a design tool where users can select the object they want to build, whether it’s a tactile wayfinding tile or a small cat bowl, as well as the location in which they want to build it. MobiPrint then heads to that precise location, fabricating the item requested on the spot using polylactic acid (PLA), a common bioplastic.

More uses

With the success of this initial prototype, Zamora is now considering how to bring MobiPrint to the outdoors.“Our lab is very passionate about accessibility and addressing social issues,” He said. “We are now thinking about what kind of engineering lift might be required to bring this outside so we could potentially print a curb at an intersection that doesn’t have one to help people who use wheelchairs or tactile wayfinding for those with visual impairment.”

He added that there is power in being able to reconfigure environments. While there are many papers in the scientific literature that talk about using extended reality (XR) applications to direct add objects in situ, a future MobiPrint could potentially allow users to communicate with the printer using VR to modify models on the fly. This would offer users more control and customization to print different objects.

He also said there is value in pursuing a device that can 3D print on the walls or ceiling. “Right now, this kind of printing is focused on the ground,” he said. “But now we are trying to figure out if we could use a drone to print something on the façade or interior walls of a building. You can imagine we could create decorations or scaffoldings for plants. So, we are also exploring how to print on a vertical surface.”

More For You: Miniature Robots to Navigate Blood Vessel Networks

The end goal, He said, is to create a full pipeline of devices that allow users to “design, control, and fabricate.” Zamora agreed—and said he hopes that engineers will start to focus on new ways of integrating or working with 3D printers to change the future of digital fabrication workflows and what they can do to customize spaces.

“It may seem like a simple idea at first—putting a 3D printer on a robotic vacuum,” Zamora said. “But it opens up a lot of bigger questions to explore.” Questions include, “How do you integrate these different systems to add new capabilities?” or “How do you design for a new pipeline of these kinds of machines?”

Zamora added, it may not “make sense to use a typical slicer where you don’t have any information about the environment if your machine now has the ability to get that. There’s a lot we can do to make the environment more accessible or just make it more suited to your needs. We just need to explore these kinds of questions.”

Kayt Sukel is a technology writer and author in Houston, Tex.